Need a Superflat Concrete Floor?

At BMD Materials, situated at 780 Bradford Street, Winnipeg, Manitoba, we specialize in delivering state-of-the-art commercial flooring solutions. Our expertise in superflat floors positions us as the premier choice for developers and contractors across Manitoba seeking unparalleled flooring expertise.

Superflat floors are essential in environments requiring precise flatness and levelness, such as warehousing and distribution centers. These floors ensure the smooth operation of lift trucks and other handling vehicles, crucial in high-density storage spaces. Originating in the 1970s, superflat floors have evolved to meet increasing demands for performance and safety, with specialized construction techniques ensuring adherence to strict specifications.

At BMD Materials, we understand the intricacies of these requirements. Our team employs advanced methods, like strip pouring, and uses the Fmin tolerance system to construct floors that not only meet but exceed industry standards. Our approach guarantees optimized lift truck performance, reduced maintenance costs, and eliminates picking issues, ensuring a seamless operation in your facilities.

We emphasize the importance of avoiding common specification errors and ensure each project is meticulously planned and executed. Our expertise spans across various applications, not limited to warehousing but extending to office buildings, stadiums, gymnasiums, and more, where precision flooring is paramount.

Choosing BMD Materials means opting for a partner who understands the critical role of flooring in your operations. Our commitment to quality, efficiency, and customer satisfaction has made us the most trusted source for commercial flooring in Winnipeg. We invite developers and contractors to join us in creating spaces that are not only functional but also safe and efficient.

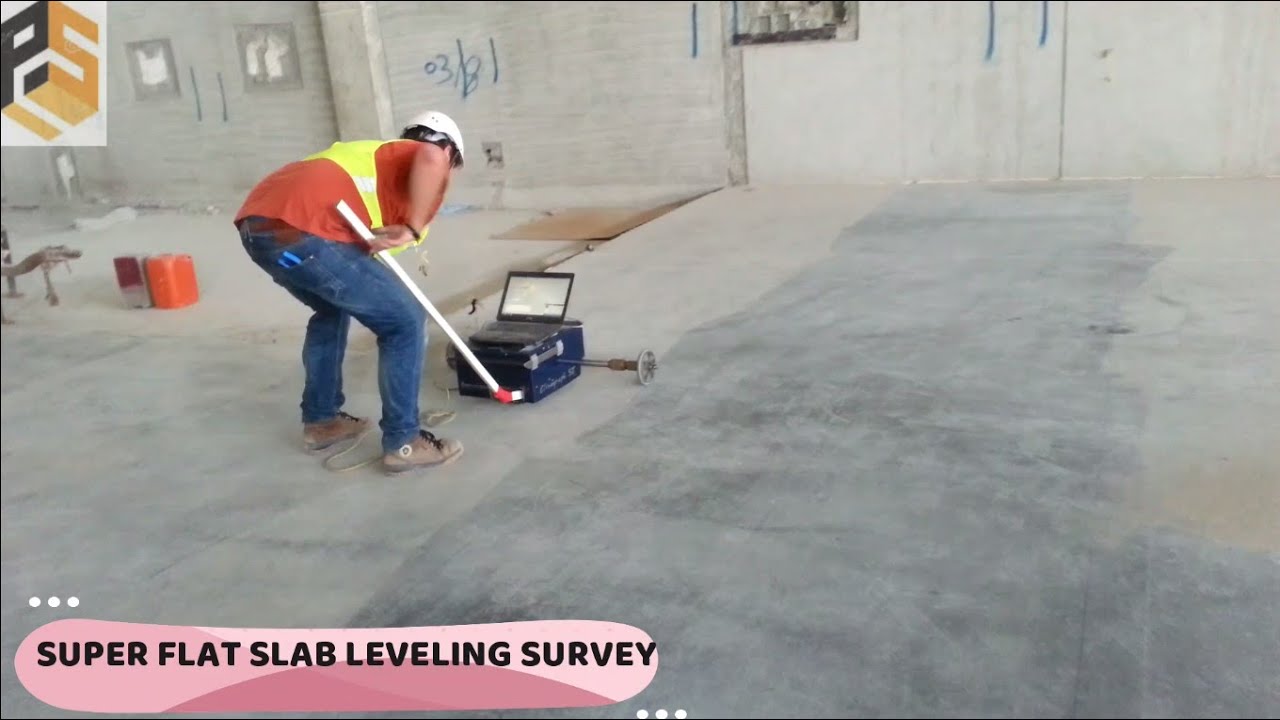

How are SuperFlat Floors measured?

Fmin Tolerance Requirements

The Fmin system of measurement and tolerance definition requires that defects over the maximum allowed variation are corrected by grinding them down. The Fmin tolerance requirements for any floor surface are based on the maximum allowed rate of change per foot of travel for a lift truck in the longitudinal direction. You should obtain that information from the manufacturer of your lift truck.

Here are some examples of common Fmin tolerances:

- 0.040 inches: Fmin100

- 0.050 inches: Fmin80

- 0.060 inches: Fmin65

- 0.070 inches: Fmin55

- 0.080 inches: Fmin50

The higher the Fmin tolerance, the flatter and more level the floor is. Fmin100 is the most common tolerance, and Fmin50 is the lowest used. Because lift trucks travel the same route over and over again, the smoothness of the wheel paths in these aisles is extremely important. Superflat slabs are laid in narrow, long strips roughly 15 feet wide. You need to confirm the tolerance of the wheel tracks in the longitudinal and transverse directions.

The superflat Fmin100 tolerance is based on a change of 1/8 inch in elevation from a 10-foot-long level plane. The wheels on VNA lift trucks are usually 5 feet apart, which requires a tolerance of a 1/16-inch change in elevation. The tolerance is altered to correspond with the dimensions of the lift truck.

What to know more?

For more information about our superflat floor solutions and other services, visit us at www.bmdmaterials.com, or drop by our office at 780 Bradford Street, Winnipeg, Manitoba, R3N0H5. Let's build the foundation for your success together!